WEBER KSN

Automatic Sanding Machine

The automatic sanding machine from WEBER for wood sanding, veneer sanding and lacquer sanding

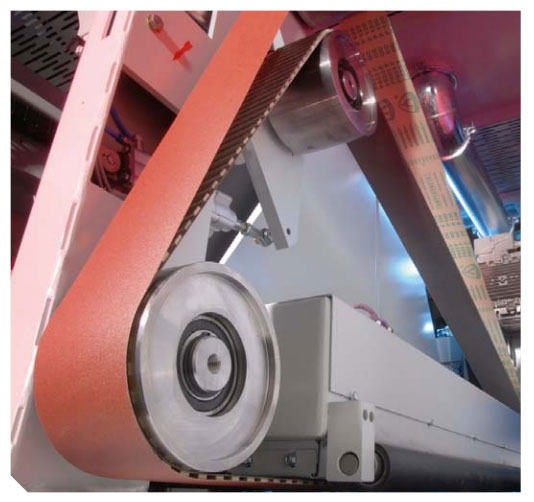

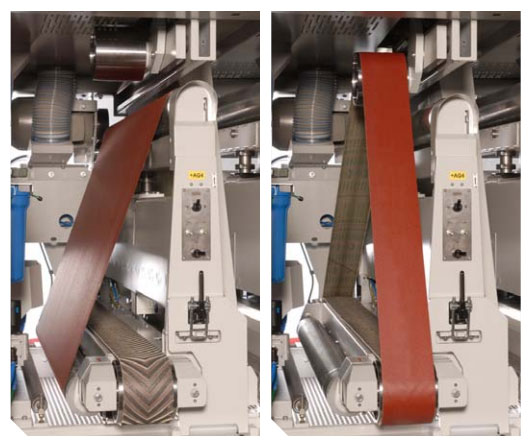

``````````The WEBER KSN series is a completely redesigned automatic sanding machine for wood sanding, veneer sanding and lacquer sanding for artisans and industry. Up to 4 sanding stations allow for all machining variations. All the WEBER sanding and brushing stations can be installed in any order, to suit requirements.

The design of the WEBER KSN demonstrates a new wood sanding dimension – not only visually.

Thanks to uncompromisingly clean lines and ergonomically well-designed, the WEBER KSN

is one of the most modern automatic sanding machines on the market.

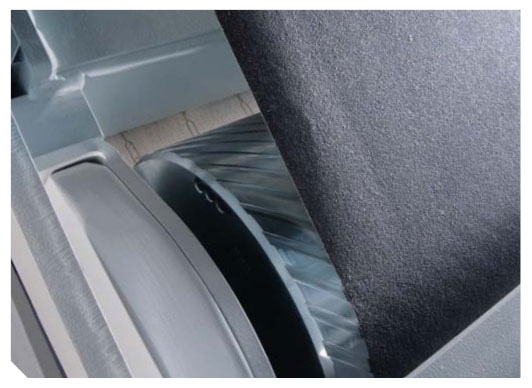

Due to the angled corner positioning, the operation terminal permits better and faster access; all

connections can be installed systematically from the top. Unimpeded vision of the machining

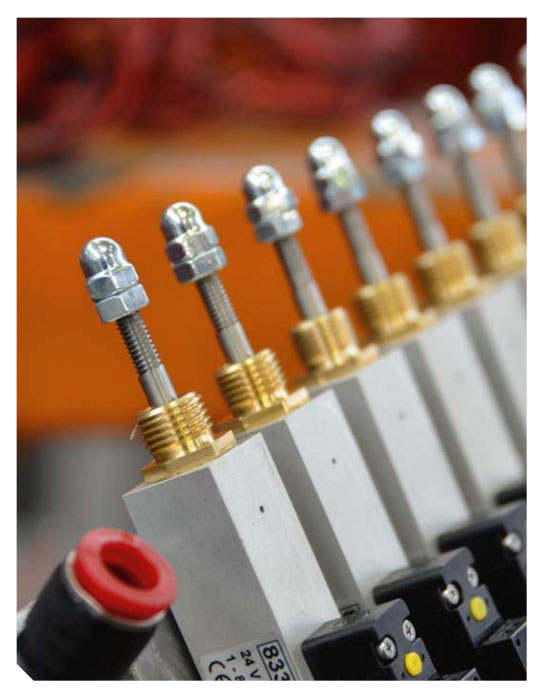

stations is possible thanks to the large vision panel. Access to all electronic and mechanical parts

assists maintenance considerably.

WEBER KSN

Operating widths upwards of 1350 and 1600 mm |

Vacuum blower integrated in the machine frame |

Version with 1 to 4 sanding stations |

Modular machine concept |

Calibrating roller drive up to 24 kW |

"i-Touch“-controller |

Lacquer finishing package |

Universal sanding lamella |

Sanding belt drive with frequency control |