WEBER TNA

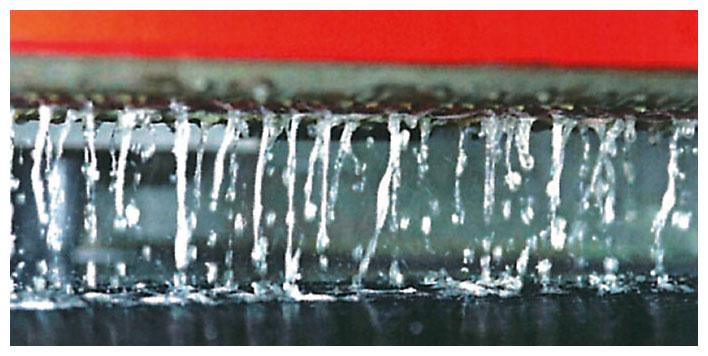

Compact wet deburring for fine blanking parts

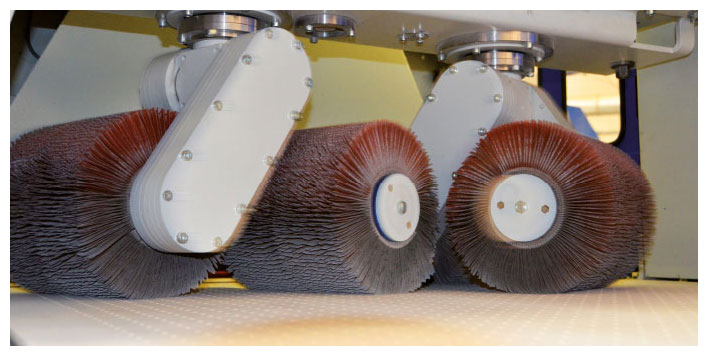

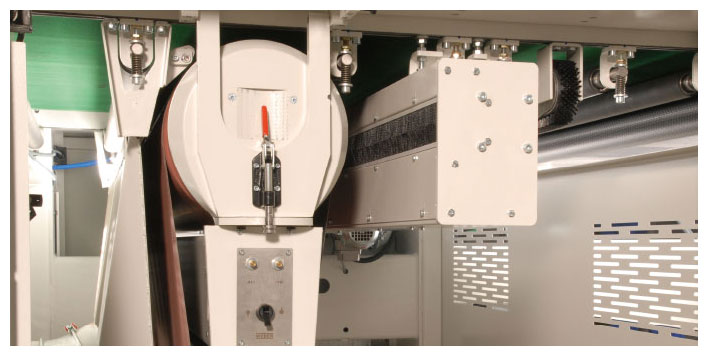

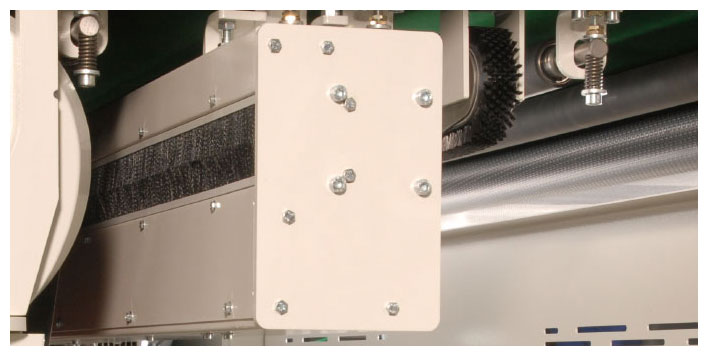

``````````The WEBER TNA is afully automatic 4-shift operation deburring machine specifically for fine-blanking parts to offer a cost-efficient option for deburring, rounding or for processing the secondary burr as a downstream machine for surface grinding. As the "compact sister" of the successful WEBER NLCA, this series is a space-saving model with the highest quality.

WEBER TNA Technical Data

Working width 300 mm |

Grinding belt length 2620 mm |

Working height 1000 mm (constant) |

Grinding belt drive up to 30 kW |

Version with 1 to 2 machining stations per frame unit |

Multi Panel |

Mode of operation: top grinding |

“i-Touch” controller |

Workpiece thickness 0.3-40 mm |

Freely selectable arrangement |

Infinitely variable feed speed (0.5 - 10 m/min) |

|